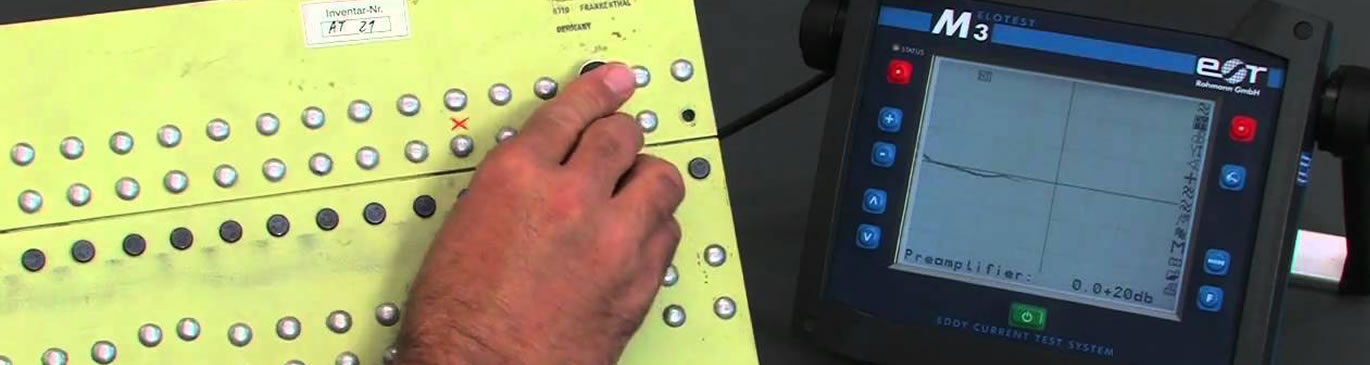

In an eddy current testing a circular coil carrying current is placed in proximity to the test specimen .The alternating current in the coil generates changing magnetic field which inter-acts with test specimen and generates eddy current. Variations in the phase and magnitude of these eddy currents and variations in the electrical conductivity or magnetic permeability of the test object, or the presence of any flaws, will cause a change in eddy current and a corre-sponding change in the phase and amplitude of the measured current.

ET Advantages:

- Sensitive to small cracks and other defects.

- Detects surface and near surface defects.

- Inspection gives immediate results.

- Equipment is very portable.

- Method can be used for much more than flaw detection.

- Minimum part preparation is required.

- Test probe does not need to contact the part.

- Inspects complex shapes and sizes of conductive materials.