Liquid Penetrant Testing (PT): Precise Surface Flaw Detection

Liquid Penetrant Testing (LPT) is an extremely powerful test method named non-destructive testing (NDT). It is highly useful in defect detection in many materials, particularly surface-breaking defects, i.e., very small cracks, pores, or seams. Integrity also matters most when it comes to providing safe and wholesome parts that are essential in the industry.

The common and quite famous method, which can also be referred to as the dye penetrant inspection. Its area of operation includes the Aerospace industry, maritime, oil and gas industry, as well as the manufacturing industry. The industries that practice the detection of surface defects in the right manner include the following. The most critical information will be retrieved in the micro-range of contact with the surface of the material by any direct observation, or any highly susceptible fluorescent (susceptibility in whose fluorescence property the excitation is done by the UV lights) penetrant, PT.

What is Liquid Penetrant Testing (PT)?

Liquid penetrating testing (PT) refers to one of the tools of exceptional power in the process of identifying open discontinuities that are open to the surface of a material. The PT makes use of a capillary effect as compared to the processes that expose magnetic fields.

An exotic liquid penetrant is applied onto the surface of a piece according to the principle. This is an oily liquid that penetrates into any cracks that are visible microscopically. The unnecessary then is washed away, and a developer is applied after some time. The developer is then used to draw the penetrant out of the defects, leaving a trace slightly visible on the surface. It is a quality control procedure that can never be discarded as far as detecting flaws is concerned. It constitutes a very important aspect of non-destructive testing (NDT).

The Liquid Penetrant Testing Take.

The Liquid Penetrant Testing is easy to do. It allows visible defects and cracking on the surface of an object, which otherwise are not visible:

- Surface Cleaning: This is the initial step, including the cleaning of the surface of the component to be serviced. This is a major pre-cleaning method that removes all contaminants, which may be dirt, grease, oil, paint, or rust. Smooch-smooch-smooch-free surface will be able to ensure that it penetrates well into any fine surface that opens with the help of the penetrant.

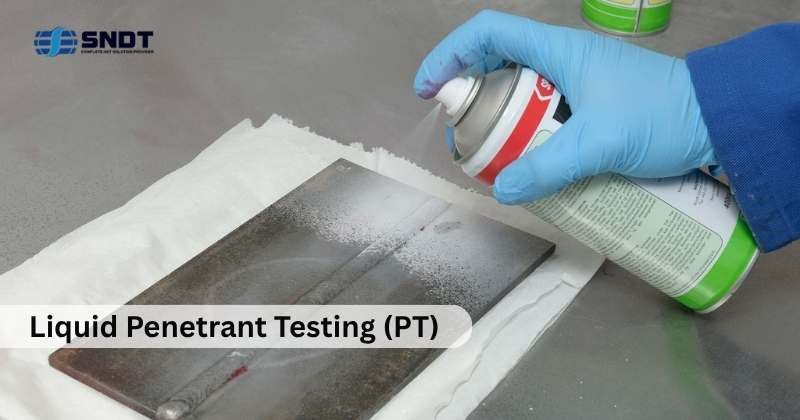

- Penetrant application: We apply a liquid penetrant. This may be a light-coloured dye (To be checked out with the eyes) or a fluorescent dye (To be checked out with a UV light). Once the surface is cleaned, the penetrant is put on it and spreads everywhere, trickling in all directions and flowing into every hole remaining on the surface left by the capillary force.

- Dwell Time: It is a time interval given out beforehand so that the penetrant can be allowed some time on the surface. The time allows the penetrant to flow into the smallest cracks. Time is also one of the variables, and this variable is dependent on the material and temperature, as well as on the nature of the flaw, which is anticipated.

- Excess scrubbing: The technicians would then scrub away the excess penetrant off the surface after the dwell time. We wipe with cleaner or water, and we ensure that the surface is free of penetrant. Penetrant inside the flaws must be encapsulated.

- Coating the Developer: Next, the developer is evenly coated. This is blotter-like, with properties of white and porous powdery form. It also sweeps out the flaws of the penetrant. The penetrating bleeding out will further result in the spreading of the penetration fluid on the surface, which will enhance and develop a better and clearer indication.

- Final Inspection: The last one is our final inspection, when we have the proper check-up of the surface that we have with the lights to make sure that it is done by our experts properly. In order to test the penetrant ingredient, we should employ white light with a visible penetrant and UV-A in the case of a fluorescent penetrant. A crack or any other defect is shown as clear and contrasting marks in the background of the developer.

Applications of PT: Where it is Applied

The Liquid Penetrant Testing is immensely useful in identifying the flaws in the welds, casting defects, and general quality control, which is beneficial in numerous industries:

- Aerospace: It is important when performing aerospace inspections on engines, airframes, and landing gears. This is used in locating manufacturing defects and fatigue cracks.

- Marine: We apply it extensively when checking the hull of ships, propellers, offshore structures, and pressure vessels. This involves the detection of cracks in the shaft as well as in the general surface integrity.

- Oil & Gas: We use PT in pipelines, storage tanks, valves, and drilling equipment. It aids in inspecting flaws in welding as well as identifying the presence of stress corrosion cracking.

- Manufacturing: It is quite vital in the detection of casting defects and inspection of forged parts, machined parts, as well as non-porous ceramics. This will guarantee the quality of the products produced before assembling or when delivered.

Benefits of Choosing PT (Advantages)

Liquid Penetrant Testing has some wonderful benefits, and as such is a favourite visual NDT procedure:

- Very Sensitive to Surface Flaws: PT is known to be very sensitive to very fine and shallow, surface-breaking defects, which usually cannot be seen with the naked eye.

- Cost-Effective: It is usually a cheap NDT technique. The instruments that are needed are also rather cheap compared to numerous other methods of testing.

- Fast Results: The test is normally speedy, hence we have speedy defect results. This assists us in attaining short lead times in inspection.

- Portable Equipment: The machines are mostly lightweight and can be transported. This enables the inspection in both types of field conditions and even in difficult-to-access locations.

What PT Can’t Do (Limitations)

Although it has its advantages, Liquid Penetrant Testing comes with certain limitations of inspection:

- One is Surface-Only Defect Detection: PT is only able to detect surface-breaking defects. It just cannot find faults that are purely self-contained in the material.

- Porous Materials: Porous materials, such as wooden objects or unglazed ceramics, do not respond well to this procedure. The penetrant would absorb evenly, and this would not show signs of defects. PT requires non-porous materials.

- Needs Clean, Smooth Surfaces: To perform to the best potential, PT should have a smooth and relatively clean surface. When a surface is either dirty or rough, it requires a lot of surface prep, which is therefore time-consuming and costs extra money to complete the inspection.

Quality Standards and Certifications

The credibility of Liquid Penetrant Testing depends on effective references to international standards and adequate certification of technicians. Coverage of complete NDT compliance by SNDT includes:

- ASTM E165: This is the practice standard of Liquid Penetrant Examination – used in general industry.

- ISO 3452: This is about non-destructive testing – Penetrant testing – General principles.

Our PT technicians are certified bodies (usually Level II or Level III) awarded by reputable institutions. This implies that they implement international standards of testing through superior knowledge and accuracy.

Why Choose SNDT for PT Services

By selecting SNDT Liquid Penetrant Testing (PT) services in Singapore, you will be dealing with an expert who leads in the field of quality and reliability. We have strong experience in the industry, so we really know the peculiarities of the sectors. We provide mobile NDT and on-site services on a flexible basis. We have highly trained personnel and modern equipment that can be transported to your premises. This offers you optimum convenience and minimum interference. We are devoted to safety, where turnarounds are carried out in the quickest time possible without affecting accuracy or work quality. Besides this, all our inspection work and reporting work are in accordance with strict international standards such as ASME and ISO. This will ensure dependable quality assurance and high-quality, believable reporting of your vital assets.

Conclusion

Liquid Penetrant Testing (PT) cannot be faulted as a sure means of detecting cracks on surfaces. It plays a very important role in the security and integrity of critical parts in many industries. It is efficient, possesses a large level of sensitivity, and is not necessarily destructive to the product under analysis, which makes it the foundation of efficient quality control, and it becomes an essential part of any efficient asset management program. Make your operations more reliable and promote the safety of your critical assets with the help of the trusted Liquid Penetrant Testing services provided by SNDT.